Coastal Material Handling – Pallet Racks | Forklifts | Shelving | Material Handling Equip…

New Pallet Rack

Pallet Racks and Storage Systems for Efficient Warehouse Storage

Why Choose New Pallet Racks?

- Teardrop

- Structural

- Keystone

- Shaved Rivet

- Interlake Mecalux

- Ridg-U-Rack

- Republic

- Sturdi-Bilt

- Speedrack

- Husky

- Tri-Boro

Benefits of New Pallet Rack

Quality and Durability

Our new pallet racking is manufactured using the latest materials and technologies, ensuring high quality and durability. Moreover, it is designed to meet industry standards and regulations, providing a reliable and long-lasting storage solution for your business.

Customization Options

Additionally, when purchasing factory-new pallet racks, you have the flexibility to choose from a wide range of sizes, configurations, and accessories to fit your specific storage needs. In particular, you can customize the racks to maximize space utilization and optimize your warehouse layout for improved efficiency.

Improved Efficiency

Furthermore, new racking systems are designed with modern features and innovations that enhance operational efficiency. For instance, they may include adjustable beams, quick assembly systems, and improved accessibility, making it easier to load and unload products and improve workflow.

Compliance With Industry Standards

Finally, many industries have specific requirements for pallet rack systems. By purchasing new racks, you can ensure compliance with these standards. This is especially important in regulated industries such as pharmaceuticals, food storage, or manufacturing, where safety and efficiency are top priorities.

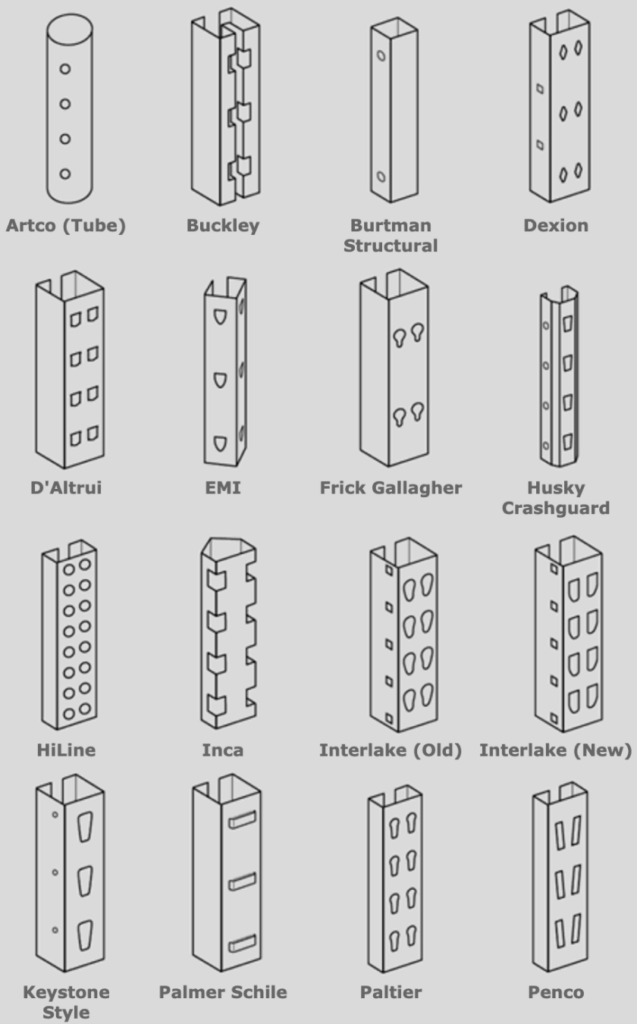

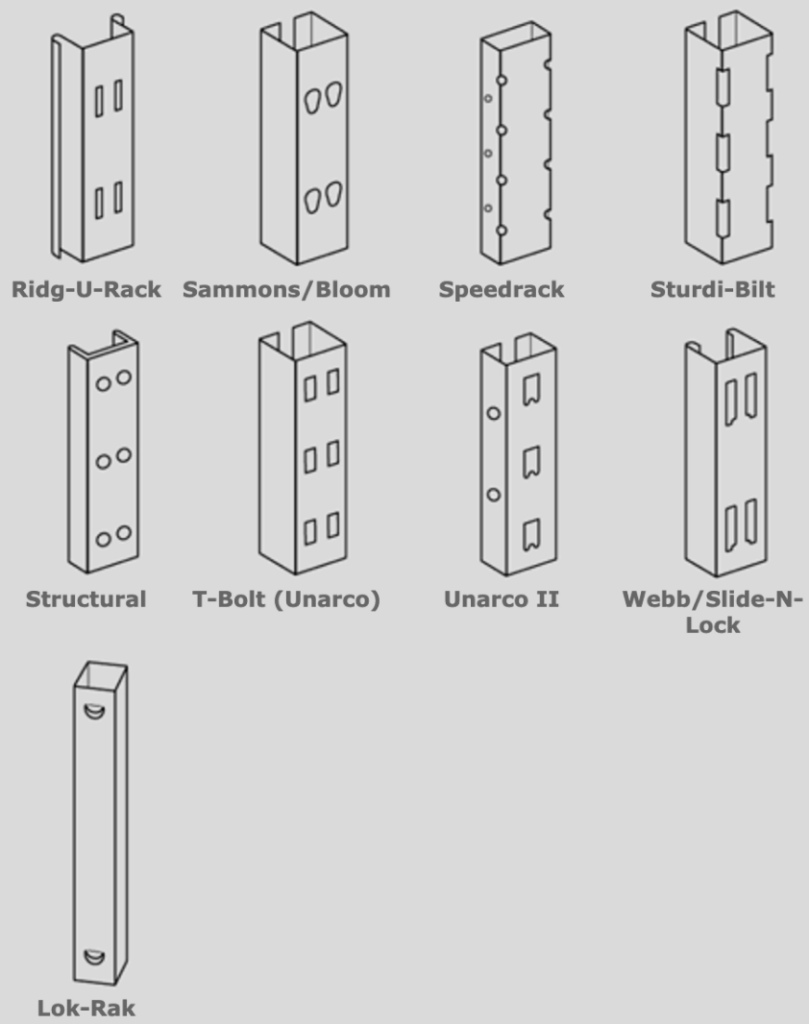

Rack Identifiers

Need to identify the Pallet Rack you already have? Here’s a handy guide. The pictures below will show you the basics.

Remember to measure the depth of the upright, the height of the face of the pallet rack beams and the vertical distance from center to center of the pallet rack beam connector holes. This will help us find the right rack to match your existing material.

FAQ’s About New Pallet Racks

What Is Teardrop Pallet Rack?

A teardrop pallet rack serves as a highly efficient storage shelving system commonly used in warehouses. More specifically, it features an inverted teardrop-shaped hole connector, which securely holds the pallet rack beams in place without requiring additional hardware. If you need assistance selecting the right warehouse system for your application, call CMH at (757) 465-8338, and our experts will gladly help. Additionally, we offer pallet racks for sale with fast service and competitive pricing.

What Is Selective Pallet Rack?

Among the various racking options available, the most common style is the Selective Pallet Rack, specifically designed for high-density warehouses storing a diverse range of products. Notably, our high-quality selective rack ensures 100% access to all pallet positions at all times, eliminating the need to move other pallets. Furthermore, this selective rack stands out as one of our top warehouse racking solutions, thanks to its easy installation and reconfiguration capabilities should storage dimensions change. If you’re looking for the right racking system for your needs, call CMH at (757) 465-8338, and we will assist you. Likewise, we provide warehouse racking for sale with prompt service and cost-effective pricing.

How About Drive-In Rack?

For a more compact storage system, the Drive-In Rack proves ideal for applications that follow the ‘Last In, First Out’ (LIFO) inventory control method. This system stores pallets on rails, with front-end access, while also allowing pallets to be positioned back-to-back to create a denser storage area. As a result, Drive-In Rack serves as an excellent solution for warehouses managing products that move quickly in and out. To find the best warehouse shelves and racks for your needs, call CMH at (757) 465-8338, and our team will guide you through the selection process. Additionally, we offer warehouse racking with fast service and competitive pricing.

What Is Push-Back Rack?

Push-Back Rack operates using the LIFO inventory control method, much like Drive-In Rack. However, instead of rails, pallets are stored on carts that move along tracks. Unlike selective racks, which store pallets in a single-deep system, push-back racks can accommodate pallets from two to five deep. As each pallet is picked, the material behind it smoothly rolls forward on rails. Furthermore, all levels remain individually accessible, maximizing storage efficiency. If you need guidance in selecting the right racking system, call CMH at (757) 465-8338, and our team will provide expert assistance. Likewise, we offer warehouse racking solutions with reliable service and budget-friendly pricing.

How is Pallet Flow Rack Different?

On the other hand, a Pallet Flow Rack incorporates a combination of elevated rails, wheels, and rollers, making it the perfect solution for high-density storage operations using the ‘First In, First Out’ (FIFO) inventory method. Particularly in warehouses with limited space, pallet flow rack proves advantageous, as it can reduce aisle space by up to 75%. When a pallet is picked, the material behind it gently rolls forward on rails, ensuring seamless product movement. Moreover, all levels remain individually accessible, improving overall efficiency. If you’re interested in optimizing your storage space with pallet flow racks, call CMH at (757) 465-8338, and we will assist you.

What Is The Difference Between Pallet Rack And Industrial Shelving?

Industrial Shelving is used for storing small parts and boxes that will be loaded by hand. It’s ideal for operations that don’t have room for, or access to a powered lift. These shelving units can be free-standing or bolted together. Pallet racks are heavy duty storage racks found in warehouses, distribution centers, and big-box retailers. Product is stored on pallets and loaded with a forklift or other powered industrial truck. Additionally, pallet rack is taller and wider than shelving. Call CMH at (757) 465-8338 and we will assist you in getting the right warehouse racking solution for your application. We offer pallet racks for sale with quick service and affordable pricing.

Is There A Standard Size For Pallet Rack?

There is no single standard size for pallet rack as it depends on your specifications, however, most common height for pallet rack frames is 16′. We supply frames available from 8′ all the way to 60′ high. Depths range from 18″-72″. Pallet rack beams range in length from 4′ to 16′. The most common pallet rack beams are available in lengths between 8 feet and 12 feet, depending on the application.

Should I Use Wire Decking With My Pallet Racks?

Wire decking is the recommended material for pallet rack decking. Many municipalities have local fire codes requiring the use of wire decking.

What Are Row Spacers?

Row Spacers provide a consistent amount of distance between two rows of pallet rack. They have a flange on each end to secure the spacer to the frame. Row spacers should be installed when there are multiple bays in a continuous row.

What Is Pallet Rack Netting?

Pallet Rack Netting is hung behind or underneath a pallet rack system, preventing product that has fallen off the racks from making it all the way to the ground. This protects your employees from injury as well as potentially reducing damage to fallen product.

Should I Anchor My Pallet Rack System To The Floor?

The simple answer is yes. You should always anchor your pallet rack to the floor. The footplates on your uprights offer specific locations to place your anchors, which are essential to prevent your warehouse racks and the entire rack system from falling over as well as for enforcing uniform aisle spacing.

How Do I Determine What Size Racks I Will Need?

It is easy to figure out what size rack you will need. First, determine the load depth, width, and height of your pallets. Then, call CMH at (757) 465-8338 to assist you in getting the right racking system for your application. We offer warehouse racks and warehouse shelving for sale with quick service and affordable pricing. Coastal Material Handling specializes in on-site service where we customize warehouse shelving systems that are customized for your application.

Do You Ship Material?

Yes, we ship pallet racks both locally and nationwide. For more information regarding shipping, please call our sales team at 757-465-8338.

Get Started With Us Today!