Coastal Material Handling – Pallet Racks | Forklifts | Shelving | Material Handling Equip…

Streamlining Warehouse Operations: Effective Warehouse Management through Organization and Systems

Home » Streamlining Warehouse Operations: Effective Warehouse Management through Organization and Systems

In the fast-paced world of logistics and e-commerce, efficient warehouse management is essential for businesses to stay competitive and meet customer demands. Effective organization and well-implemented systems play a pivotal role in optimizing warehouse operations, reducing costs, and increasing overall productivity.

Where should we start?

The Importance of Effective Warehouse Management

Warehouse management is more than just moving goods from one place to another. It encompasses all activities related to the storage, retrieval, and handling of inventory. Efficient warehouse management is crucial for various reasons:

- Cost Reduction: Properly managed warehouses minimize unnecessary costs, such as overstocking, understocking, and operational inefficiencies.

- Improved Productivity: Well-organized systems and processes lead to higher productivity levels, enabling the warehouse to fulfill orders faster.

- Enhanced Customer Satisfaction: Efficient warehouse management ensures that products are readily available for shipping, which results in faster order fulfillment and improved customer satisfaction.

- Inventory Accuracy: Effective systems help maintain accurate inventory counts, reducing the risk of stockouts and overstocking.

Now, let’s delve into the strategies for achieving effective warehouse management.

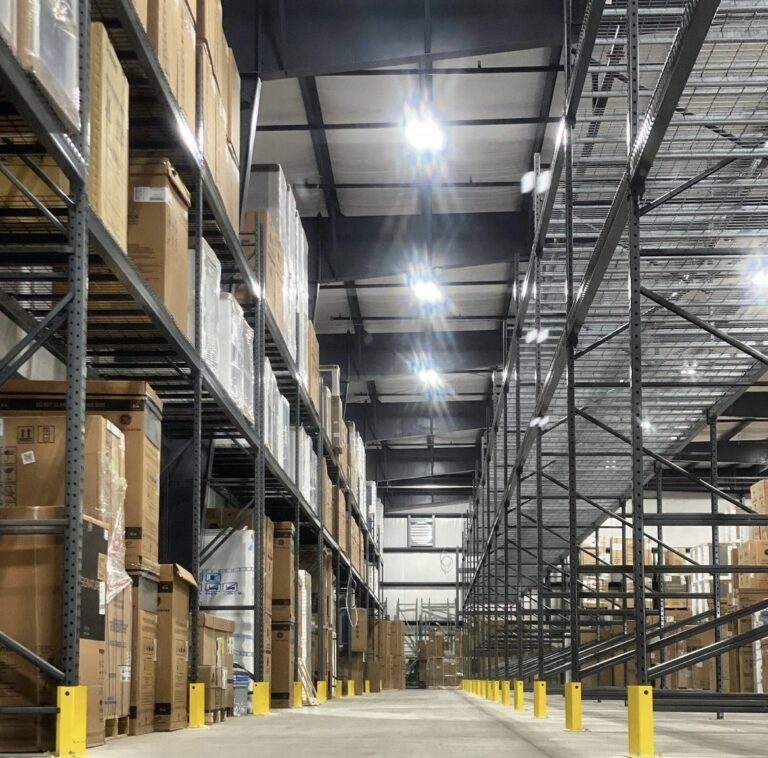

Organized Layout and Space Utilization

An organized warehouse layout is the foundation of effective warehouse management. Consider the following aspects:

- Zoning: Divide the warehouse into zones, each dedicated to specific products or operations. This makes it easier to locate items and manage inventory.

- Proper Shelving: Implement racking and shelving systems to maximize vertical space. Make sure to label shelves and bins for easy identification.

- Aisles and Walkways: Ensure clear and easily accessible pathways to facilitate the movement of goods and reduce the risk of accidents.

- Efficient Slotting: Assign storage locations based on product popularity and order frequency, placing fast-moving items closer to the packing area.

Inventory Management Systems

Invest in a robust inventory management system to keep track of your inventory in real-time. This system should:

- Provide accurate stock levels and product locations.

- Generate automatic reorder points and alerts for low stock.

- Enable easy integration with your e-commerce platform and order management system.

- Offer reporting and analytics to track trends and make data-driven decisions.

Order Fulfillment and Picking Strategies

Implement efficient order fulfillment and picking strategies to minimize errors and streamline processes.Consider strategies like:

Batch picking: Combine multiple orders with similar products into a single pick list to reduce travel time and increase efficiency.

Pick-to-light or voice-picking systems: These technologies guide workers to the right items, reducing errors and speeding up the picking process.

Technology Integration

Modern warehouse management relies heavily on technology. Integrate systems and tools that enhance efficiency:

- Warehouse management software (WMS): Automate inventory tracking, order processing, and reporting.

- Barcode and RFID systems: These technologies simplify tracking and reduce human error.

- Automated material handling systems: Consider automation for repetitive and labor-intensive tasks to improve efficiency.

Workforce Training

A well-trained workforce is vital for effective warehouse management. Ensure that your team is trained in safety procedures, equipment operation, and efficient warehouse processes. Regular training and performance evaluations help maintain high standards.

Continuous Improvement

Finally, don’t forget the importance of continuous improvement. Regularly assess your warehouse operations, seek feedback from your team, and adapt to changing market conditions. Make adjustments and optimizations to stay competitive.

Effective warehouse management requires a combination of smart organization and integrated systems. By optimizing your warehouse layout, implementing advanced inventory management systems, streamlining order fulfillment, and continually improving processes, you can increase productivity, reduce costs, and enhance customer satisfaction. In a rapidly evolving business landscape, mastering these techniques is crucial for maintaining a competitive edge in the logistics and e-commerce industries.